Semua produk

-

strip baja stainless coil

-

304 Stainless Steel Coil

-

201 Stainless Steel Coil

-

316L coil stainless steel

-

430 baja Stainless Coil

-

Hot Rolled Stainless Steel Coil

-

stainless steel strip

-

rolled sheet stainless steel dingin

-

Stainless Steel Hot Rolled Plate

-

Cold Rolled Stainless Steel Strip

-

Stainless Steel Bar

-

pipa stainless steel

-

berwarna lembaran stainless steel

-

Auto Exhaust Flexible Pipe

-

stainless steel wire rod

-

Coil Baja Dicat

-

Lembaran Atap Stainless Steel

-

OEM Produk Stainless

-

OEM Produk Stainless

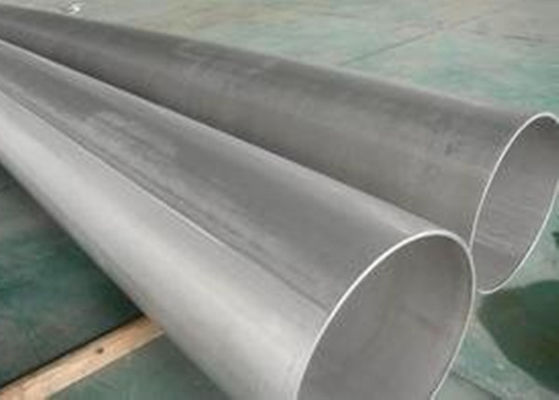

Pipa Baja Baja Diameter Besar Baik Korosi / Perlawanan Panas

Hubungi saya untuk sampel gratis dan kupon.

ada apa:0086 18588475571

Wechat wechat: 0086 18588475571

Skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan bantuan online 24 jam.

xDetail produk

| Deskripsi | pipa baja dilas | Kelas | TP304 TP304L TP316 TP316L |

|---|---|---|---|

| Nominal Diameter | 6mm-300mm | Diameter Luar | 10.29mm-323.85mm |

| Ketebalan dinding | SCH5S SCH10S SCH40S | Standar | ASTM A312 / A358 / A778 (B36.19M) |

| Panjang | sesuai permintaan | Aplikasi | Untuk pipa industri |

| Menyoroti | tabung dilas stainless steel,stok tabung stainless steel |

||

Deskripsi Produk

TP304 TP304L TP316 TP316 pipa dilas stainless steel SCH 5S SCH 10S SCH 40S

Rentang Produk

| Diameter Nominal | Diameter luar | Dinding Normal Tebal (mm) | |||

| NB | NPS | mm | SCH 5S | SCH 10S | SCH 40S |

| 6 | 1/8 | 10.29 | 1,24 | 1,73 | |

| 8 | 1/4 | 13.72 | 1,24 | 1,65 | 2.24 |

| 10 | 3/8 | 17.15 | 1,24 | 1,65 | 2.31 |

| 15 | 1/2 | 21.34 | 1,65 | 2.11 | 2.77 |

| 20 | 3/4 | 26.67 | 1,65 | 2.11 | 2.87 |

| 25 | 1 | 33.4 | 1,65 | 2.77 | 3.38 |

| 32 | 1 1/4 | 42.16 | 1,65 | 2.77 | 3.56 |

| 40 | 1 1/2 | 48.26 | 1,65 | 2.77 | 3.68 |

| 50 | 2 | 60.33 | 1,65 | 2.77 | 3.91 |

| 65 | 2 1/2 | 73.03 | 2.11 | 3.05 | 5.16 |

| 80 | 3 | 88.9 | 2.11 | 3.05 | 5.49 |

| 90 | 3 1/2 | 101.6 | 2.11 | 3.05 | 5.74 |

| 100 | 4 | 114.3 | 2.11 | 3.05 | 6.02 |

| 15 | 5 | 141.3 | 2.77 | 3.4 | 6.55 |

| 150 | 6 | 168.28 | 2.77 | 3.4 | 7.11 |

| 200 | 8 | 219.08 | 2.77 | 3.76 | 8.18 |

| 250 | 10 | 273.05 | 3.4 | 4.19 | 9.27 |

| 300 | 12 | 323.85 | 3.96 | 4.57 | 9.53 |

KOMPOSISI KIMIA

| STANDAR | KELAS | KOMPOSISI KIMIA(%) | |||||||

| Maks | Si maks | Mn maks | P maks | S maks | Ni | Cr | Mo | ||

| ASTM | TP304 | 0,080 | 1.00 | 2.00 | 0,045 | 0,030 | 8.00-11.00 | 18.00-20.00 | - |

| TP304L | 0,035 | 1.00 | 2.00 | 0,045 | 0,030 | 8.00-13.00 | 18.00-20.00 | - | |

| TP316 | 0,080 | 1.00 | 2.00 | 0,045 | 0,030 | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | |

| TP316L | 0,035 | 1.00 | 2.00 | 0,045 | 0,030 | 10.00 ~ 14.00 | 16.00-18.00 | 2.00-3.00 | |

| ASTM | Kelas | Kekuatan Hasil | Daya tarik | Pemanjangan | Kekerasan |

| KSi (Mpa) | KSi (Mpa) | % | HRB | ||

| TP304 | ≥515 | 205 | ≥35 | ≤90 | |

| TP304L | ≥483 | 170 | ≥35 | ≤90 | |

| TP316 | ≥515 | 205 | ≥35 | ≤90 | |

| TP316L | ≥483 | 170 | ≥35 | ≤90 |

Aplikasi Utama:

- Petrokimia

- Pembuatan kertas

- Energi

- Uap

- Rekayasa Limbah

Rekomendasi Produk